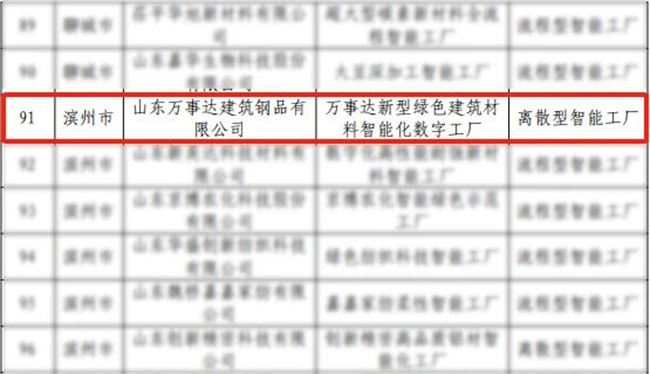

Recently, the Shandong Provincial Department of Industry and Information Technology announced the 2023 Shandong Province smart factory, digital workshop and other projects to identify the enterprise list, Shandong Wiskind Architectural Steel Co., Ltd. successfully selected "2023 provincial smart factory", not only shows Wiskind's excellent intelligent manufacturing strength, but also its authority in lean production and intelligent management.

Continuous innovation to lead the development of the industry

At present, smart factories have become the general trend of modern industry and manufacturing. The promotion of intelligent manufacturing is the internal demand for the transformation and upgrading of China's manufacturing industry, and it is also a historical opportunity for the innovation and development of China's manufacturing industry.

Wiskind architectural steel actively responded to the call of the state, adhere to innovation as the core of enterprise development, increase investment in scientific research, combined with a new generation of information technology, through digital application, improve the level of intelligent manufacturing, to achieve production efficiency improvement, quality and efficiency improvement, resource consumption reduction, operating costs reduction, environmentally friendly new smart factory, leading the high-quality development of the industry.

Multiple digital construction to improve management efficiency

With the help of digital capabilities of Siemens, SAP, Stwerk and other enterprises, Wiskind architectural steel products takes intelligent manufacturing and the integration of the two as the development direction, and aims to improve production efficiency, increase manufacturing flexibility, improve the agile delivery ability of intelligent manufacturing, improve the timeliness and refinement of inventory management, improve product quality, and improve equipment stability. By optimizing the automation architecture planning, communication protocols and interface standards, four closed-loop systems for production and operation are built to make the production status visible and controllable throughout the process, and improve the agile delivery ability.

Through one board, one object, one code, to achieve production information recording and tracing, to achieve the whole process of data statistics and analysis, etc., to lay a good foundation for the construction of smart factories, while having replicable, scalable experience, improve the company's green, low-carbon and high-quality development level.

Peroration

In the future, Wiskind architectural steel will continue to take intelligent manufacturing as the main direction to promote the company's high-quality development, in-depth exploration of the company's potential and application in digital technology, equipment, production, equipment and logistics, and continue to improve the intelligent level of equipment operation and production process, accelerate the pace of transformation to intelligent manufacturing, and empower the "industrial brain" with digitalization. Contribute to the intelligent development of the industry!